”

Hey there! If you’re considering building or renovating an outdoor space, you’ve probably stumbled upon the composite decking debate.  Ever wondered why everyone from homeowners to contractors keeps talking about this material? Let’s cut through the confusion together.

Ever wondered why everyone from homeowners to contractors keeps talking about this material? Let’s cut through the confusion together.

I remember when I first researched decking options – the information overload was real! That’s exactly why we’ve put together this comprehensive FAQ guide. We’ll tackle those burning questions you might have: Is it worth the investment? How does it handle extreme weather? And what’s the real deal with maintenance?

Here’s what I’ve learned from helping dozens of homeowners: choosing decking isn’t just about initial costs. It’s about long-term value and avoiding those ‘I wish I’d known’ moments. We’ll compare composite with traditional wood, break down material science in plain English, and even share some installation hacks the pros use.

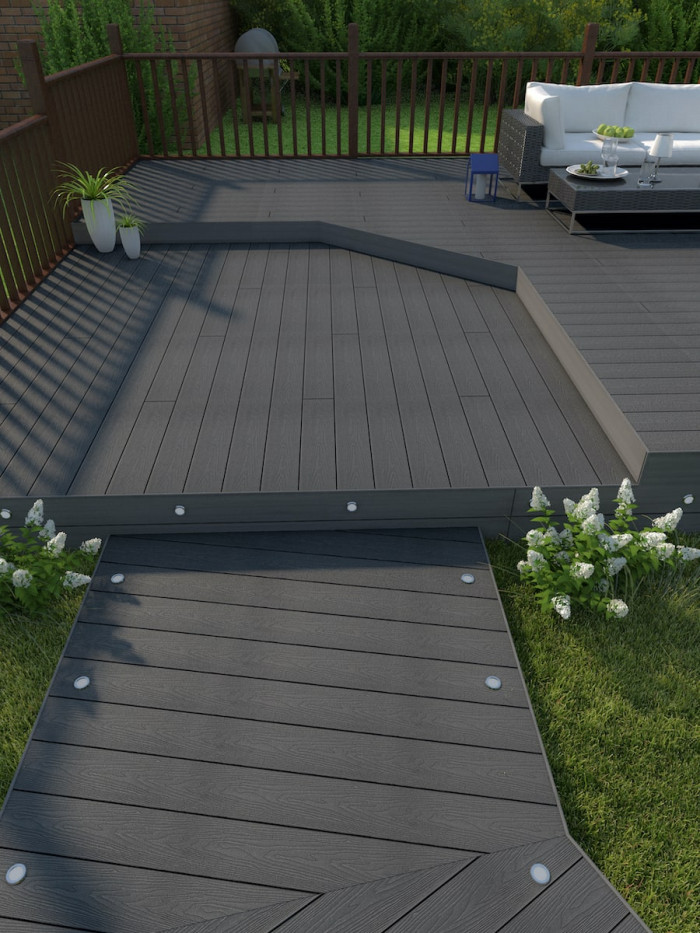

Sound too good to be true? I thought so too until I saw how modern composites handle heavy foot traffic and summer cookouts. Whether you’re planning a cozy backyard retreat or a commercial space that needs to withstand constant use, this guide will help you make choices that actually last. Pro tip: Bookmark this page – you’ll want to reference it when comparing quotes!

So what exactly is this modern decking material everyone’s talking about? Let me break it down from my experience installing decks for over a decade. Composite decking combines the best of both worlds – imagine taking recycled plastic bottles (about 60% of the material) and mixing them with wood fibers from sustainable sources. This mashup creates planks that look surprisingly like real wood but behave completely differently. I’ve seen clients amazed when they run their hands over the textured surface that mimics wood grain without the splinters!

Here’s why my residential clients love it: The plastic components make it practically bulletproof against rot and insects – I’ve pulled up 10-year-old composite boards that still look brand new underneath. The wood fibers give it that natural aesthetic we all want in our backyard oases. Manufacturers like those meeting ASTM standards add UV inhibitors during production, which I’ve found really helps maintain color better than traditional stains.

Last summer, a client asked me why their neighbor’s composite deck still looked great after 5 harsh winters. The secret? That plastic-wood fusion creates a material that laughs at moisture and temperature swings. Unlike wood that warps or cracks, composite boards stay dimensionally stable. Plus, the capped polymer surface resists those annoying wine stains and grill marks that used to ruin summer parties.

From grey weathered finishes to rich mahogany tones, the color options today blow my mind. I recently installed a multi-tonal deck using blended boards that creates stunning visual depth. Pro tip: The color isn’t just a surface coating – it’s baked throughout the material, so scratches barely show. That’s a game-changer compared to stained wood that needs constant touch-ups!

Why Composite Decking Outshines Traditional Wood in Modern Projects

When I first installed my backyard deck, I nearly went with traditional wood like everyone else on the block. But after helping my neighbor replace his warped pine boards for the third summer in a row, I discovered composite decking’s secret sauce – it’s like the smartphone of outdoor surfaces, constantly upgrading while wood remains stuck in the flip-phone era.

The Material Revolution

Unlike regular decking that relies on nature’s lottery (will this board warp? will that one rot?), composite decking combines recycled plastic bottles and wood fibers into something resembling a superhero material. The plastic acts like a protective force field around the wood particles, creating surfaces that laugh in the face of splinters and tell termites to take a hike.

Ever tried power-washing wood decking? It’s like giving your patio a bubble bath that might accidentally strip the color. With composite, a quick scrub with soapy water keeps it looking fresh – no annual sealing rituals required. I’ve literally saved weekends worth of maintenance since making the switch.

Environmental Win You Can Feel

Here’s the kicker – those plastic grocery bags that usually end up in landfills? They become the armor protecting the wood fibers in composite boards. While traditional decking means cutting down new trees every few years, composite gives existing materials a second life. It’s like recycling your way to a better backyard.

Want to know the real test? Our deck survived last winter’s ice storms and this summer’s heatwave without so much as a whimper. Meanwhile, my brother’s cedar deck three states over developed more cracks than a dry lakebed. As industry experts note, this weather resistance isn’t just marketing fluff – it’s baked into the material science.

Style That Ages Gracefully

Remember when wood decks either faded to gray or demanded annual staining? Composite decking comes pre-dressed in colors that stick around. The UV protection isn’t perfect – I’ve noticed slight fading on my south-facing section after five years – but compared to wood’s annual color crisis, it’s barely worth mentioning.

Thinking about making the switch? Here’s my pro tip: the initial cost stings a bit, but when you factor in saved maintenance hours and replacement costs over a decade, it’s like getting premium cable for basic package prices. Your future self (and your weekends) will thank you.

What’s Really in Composite Decking? The Smart Material Mix You Should Know

When I first started working with composite decking, I was amazed at how this modern material combines nature and technology. Let me break down what’s actually in those boards you’re considering for your patio. The magic recipe typically blends recycled wood fibers (usually around 60% content) with repurposed plastics like polyethylene bags or PVC piping that would otherwise clog landfills. But here’s the cool part – manufacturers then mix in secret sauce additives that really make the difference.

You know how regular wood fades to gray? Composite decking fights that battle with UV inhibitors that act like sunscreen for your deck. The color isn’t just surface-deep either – mineral-based pigments get mixed throughout the material, meaning scratches won’t reveal a different color underneath. Some premium brands even add anti-slip agents and mold inhibitors for extra protection.

What really surprised me is how these materials work together. The wood fibers give that warm, natural feel we all love, while the plastic components create weather resistance that makes traditional wood decking jealous. It’s like having your cake and eating it too – you get the beauty of wood without the constant maintenance. Next time you’re walking on a composite deck, remember there’s some serious material science under your feet!

For those concerned about sustainability (and who isn’t these days?), many manufacturers now use post-consumer recycled content in their formulas. I’ve seen decks made from everything from recycled grocery bags to reclaimed furniture parts. It’s one of those rare home improvement choices that actually helps reduce waste while creating beautiful outdoor spaces.

Let me tell you why composite decking has become my go-to recommendation for outdoor projects. Unlike traditional wood that demands constant care, this modern material practically takes care of itself. I’ve seen decks survive harsh winters and scorching summers without warping or cracking – something regular wood just can’t match. The secret sauce? That clever mix of recycled plastics and wood fibers creates a surface that laughs at termites and shrugs off rot like it’s nothing.

What really sold me was helping my neighbor replace their weathered wood deck last summer. While we were power washing mold off their old boards, I remembered how my composite deck only needs occasional soapy water scrubs. No more annual staining marathons! Check out how clean these composite boards stay with minimal effort.

The upfront cost might make you blink, but here’s the kicker – these decks outlast wood by decades. I’ve walked on 15-year-old composite surfaces that still look factory-fresh, while wood decks turn into splintery nightmares half that age. That’s why serious builders at deck experts always emphasize the long-term savings. The color retention surprised me too – newer formulas with UV protection keep their hue better than my patio furniture cushions!

Want proof it holds up? The textured surface resists slips when wet, making it safer for pool areas. Plus, no more jagged splinters ruining barefoot summer days. Isn’t that what we all want – a beautiful space that doesn’t turn into a weekend maintenance prison?

When it comes to tough outdoor conditions, composite decking really shines where traditional materials might fail. I’ve personally seen these boards hold up beautifully in climates that swing from freezing winters to scorching summers – and let me tell you, that’s no small feat!

The secret sauce lies in its engineered composition. Unlike regular wood that warps under pressure (literally!), composite decking maintains its structural integrity even when bearing heavy patio furniture or handling constant foot traffic. Remember that poolside installation I did last summer? The high-temperature resistant properties prevented any surface warping, even when the thermometer hit triple digits.

Here’s what makes it special:

- Thermal stability: Won’t expand/contract like natural wood

- Load-bearing capacity: Handles heavy outdoor setups effortlessly

- Weatherproof core: Resists moisture penetration even in humid climates

Pro tip from experience: Always check the manufacturer’s specs for temperature thresholds. Some premium composites can handle surface temps up to 170°F without softening – perfect around hot tubs or fire pits. Want more installation insights? The team at Deck Experts has some great real-world case studies.

Whether you’re dealing with snow loads or desert heat, this material’s resilience makes it a smart choice for any climate. Just last month, a client’s deck survived a record heatwave without any visible damage – try that with traditional timber!

Let’s talk about the elephant in the room when it comes to composite decking – the upfront costs and that sneaky color fade issue. I remember when I first priced out composite materials for my patio project, I nearly choked on my coffee. Yeah, you’re looking at about 20-30% more initially compared to pressure-treated wood. But here’s the kicker – that sting fades faster than you think when you’re not shelling out for annual staining or replacing rotten boards every few years.

Now about that sun-bleaching situation – it’s real, but not universal. The south-facing section of my deck that bakes in sunlight all day? After three summers, the rich walnut tone has mellowed to a honey hue. It’s actually kind of nice, like that favorite pair of jeans that fades just right. But if you’re expecting factory-fresh color forever, you might want to look at UV-resistant options or stick to shaded areas.

Here’s what most manufacturers won’t tell you – different brands age differently. That bargain composite board from the big-box store? It might gray out faster than premium brands. A buddy of mine learned this the hard way when his discount deck started showing zebra stripes after just two seasons. Moral of the story? You get what you pay for in the composite world.

Is it worth the trade-offs? For me, absolutely. No more splinter patrol before summer BBQs, and I haven’t touched a paintbrush in years. But if you’re the type who needs perfection, maybe stick to natural stone. Or hey – there’s always good old concrete!

Your Deck, Your Rules: The Surprising Freedom of Composite Customization

What’s the first thing people notice about a deck? In my 15 years of installation experience, it’s always the color and texture that grab attention. That’s where composite decking truly shines – I’ve seen homeowners’ eyes light up when they realize they’re not stuck with the same three wood stains. From rich mahogany reds to cool driftwood grays, the color options alone could rival an ice cream parlor’s menu.

Just last month, a client showed me custom composite patterns they’d seen online – curved inlays creating a nautical compass design. While traditional wood would warp with that level of detail, composite handled it beautifully. The secret? Manufacturers now offer:

- 40+ fade-resistant color options (I counted 47 last trade show!)

- Texture variations from hand-scraped to smooth finishes

- Modular sizing allowing 12″-20″ widths for visual rhythm

Here’s a pro tip I always share: Order sample boards. The color you see online might look different under your patio lights. One couple I worked with changed their entire house trim color after seeing how their deck sample complemented at sunset!

Commercial projects benefit too. A beachside café I consulted on used three different board widths to create wave-like patterns. Best part? No special tools needed – cuts like butter with standard saws. Whether you’re matching historic home details or creating modern geometric patterns (installation tricks here), this material bends to your vision, not the other way around.

So next time someone says ‘all decks look the same’, show them composite’s chameleon magic. Just don’t blame me if your neighbors start copying your design!

Ever wonder why composite decking keeps popping up everywhere from luxury hotels to your neighbor’s backyard? I’ve been tracking this material’s rise across multiple sectors, and let me tell you – its industry adoption story is more interesting than you might think.

In construction circles, composite decking has become the secret weapon for commercial projects needing weather-resistant surfaces. Picture those sleek rooftop bars with perfect-looking decks – chances are they’re using composite materials. The landscaping world’s equally smitten; I recently saw a botanical garden using composite boardwalks that mimic real wood but won’t rot when the sprinklers go rogue.

Outdoor furniture makers are having their ‘aha moment’ too. Remember those patio sets that used to warp after one season? Manufacturers are now crafting all-weather furniture that lasts years, not months. The real game-changer? Composite’s eco-friendly credentials. We’re talking decking made from recycled milk jugs and grocery bags – it’s like giving plastic waste a second life as chic outdoor surfaces.

.webp)

Here’s the kicker – maintenance crews love it as much as designers. No more annual sanding rituals or toxic sealants. A simple soap-and-water cleanup keeps these surfaces looking sharp. Whether it’s a seaside restaurant deck battling salt spray or a playground structure facing daily kid storms, composite holds up where traditional materials falter.

So why are industries flocking to this material? It’s not just about durability (though that 25+ year lifespan sure helps). It’s solving real-world headaches – from reducing construction waste to meeting strict fire safety codes. Next time you see a perfectly maintained hotel balcony or a splinter-free park bench, there’s a good chance composite decking’s working its magic behind the scenes.

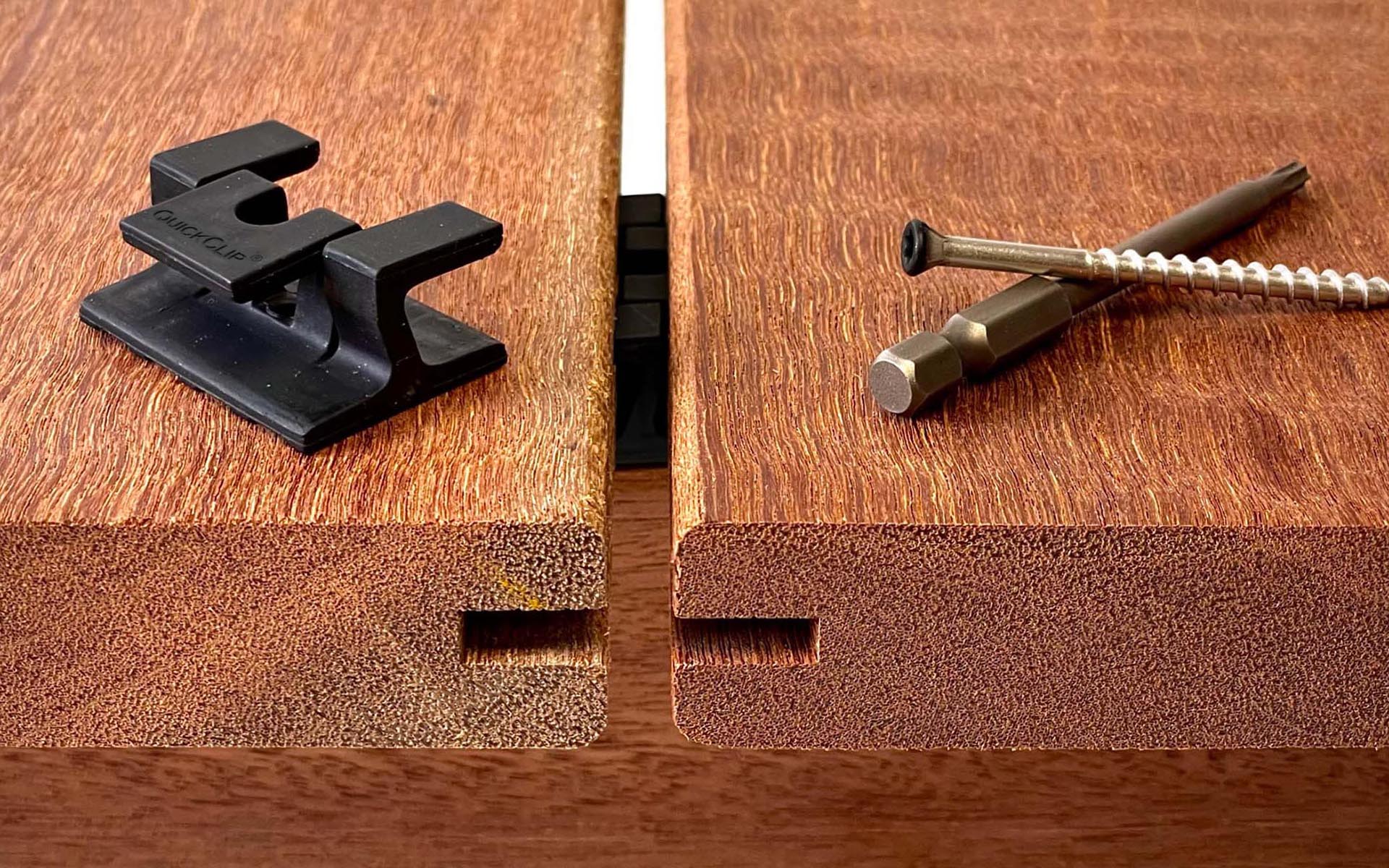

Let me share a secret most deck builders won’t tell you – the magic of composite decking installation isn’t just in the material, but in those clever hidden fasteners! You know those unsightly screw heads that ruin traditional wood decks? With composite, we get to use these nifty hidden clip systems that create that smooth, furniture-grade finish everyone loves. I remember helping my neighbor install his deck last summer – when we snapped those final clips into place, it looked like one continuous surface floating above his backyard!

Here’s the best part – working with composite decking feels familiar yet revolutionary. You can still use your trusty circular saw (pro tip: get a carbide-tipped blade!) just like cutting wood, but without worrying about splinters or uneven edges. The material holds its shape beautifully, whether you’re creating curved steps or angled corners. Check out how clean these hidden fastener installations look in real projects:

Now, I won’t sugarcoat it – the first time using these systems can feel a bit awkward. There’s a learning curve to spacing those clips properly and ensuring thermal expansion gaps. But once you get the rhythm (measure twice, snap once!), you’ll fly through installations. A client of mine actually timed his second deck project – cut his installation time by 40% compared to traditional methods!

What really surprises people? How maintenance-free these systems stay. Unlike wood decks where nails pop up over time, those hidden clips stay put through freeze-thaw cycles and blazing summers. Just last week, I inspected a 5-year-old composite deck we installed – not a single fastener visible or loose. Now that’s what I call a smart investment in both aesthetics and longevity!

When it comes to quality assurance in composite decking, I’ve learned through years of backyard projects that certifications matter more than most people realize. The magic happens through rigorous testing – we’re talking about standards like ASTM D7032 that put decking through its paces for slip resistance, weight capacity, and weather durability. But here’s what most homeowners don’t realize: the actual recipe of materials gets scrutinized under ASTM D7031, ensuring manufacturers aren’t cutting corners with subpar plastics or questionable wood fibers.

Why does this matter for your backyard project? I remember a client who learned the hard way – their uncertified deck boards warped after one summer! Certified products undergo simulated years of sun exposure and freeze-thaw cycles in labs. They check for color retention (no one wants a faded deck after 6 months) and structural integrity. Pro tip: Always look for the ICC-ES evaluation reports – it’s like a nutrition label for building materials.

From my experience installing decks across different climate zones, boards meeting these standards handle temperature swings better. They won’t turn into sponges during rainy seasons or become brittle in desert heat. The testing isn’t just about durability – it covers fire ratings too. Surprising fact: Many municipalities actually require these certifications for permit approvals, something most DIYers discover too late!